Panel Dividing: One world premiere. Three flexible workshop concepts

Experts in panel dividing technology are celebrating the world premiere of a new cutting concept at this year's HOMAG Treff, taking place at the company's Holzbronn site. With the help of a built-in robot, two new saws will combine autonomous batch size 1 production with the high flexibility of manual cutting. HOMAG is also exhibiting various production concepts in Holzbronn that make modern and flexible work in any joinery an exciting experience.

All the highlights and further innovations in Holzbronn can be seen at HOMAG Treff from September 25 to 28, daily from 9 am to 5 pm.

SAWTEQ B-300 flexTec and SAWTEQ B-400 flexTec

WORLD PREMIERE: Two robot saws for maximum versatility

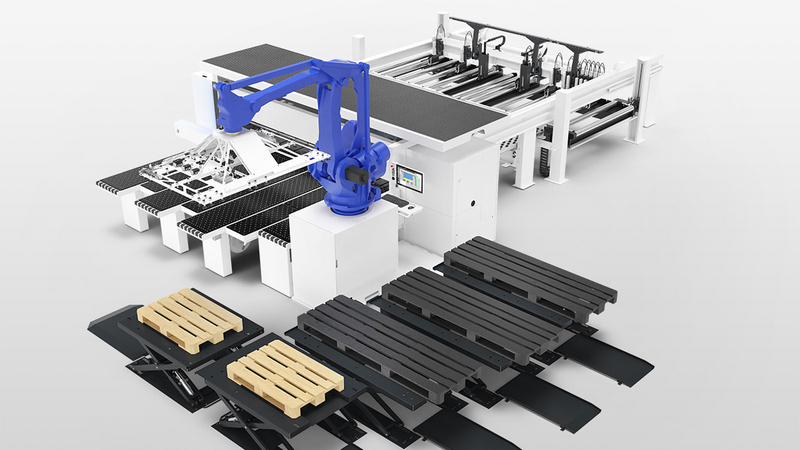

Automatically efficient. Manually versatile. Incredibly flexible. These three statements perfectly express the strengths of the new HOMAG SAWTEQ B‑300 flexTec and SAWTEQ B‑400 flexTec saws. The brand-new saw concept using robots is making its world premiere at HOMAG Treff in Holzbronn. Interested parties and customers of HOMAG saws have a lot to look forward to.

Autonomous batch size 1 production

Both process innovations are automatically efficient during autonomous batch size 1 production, as both saws use industrial robots for single-panel cutting — meaning no human intervention is required in sections. The key to this system is a highly intelligent stack formation when destacking onto lifting tables. The algorithms of the software used to achieve this have already been tried and tested using the batch size 1 cutting cell SAWTEQ B‑320 flexTec.

Tried-and-tested saw technology

Unlike the cutting cell, which was developed specifically for automated batch size 1 cutting processes, the SAWTEQ B-300 flexTec and SAWTEQ B‑400 flexTec saws can be operated manually if required. This may be advantageous for applications such as cutting books, dividing thin panels or for special functions such as adding multiple grooves to a panel. The two new saws are incredibly versatile as a result. It's also useful to know that the design and features of the basic models of the new saws are largely the same as the SAWTEQ B-300 and the SAWTEQ B-400, even retaining the same level of reliability offered by these panel dividing classics.

Demand-based solutions

The two new saws offer an outstanding level of flexibility thanks to the combination of optimum robot performance and manual operating freedom for cutting process. There are countless designs available in a range that includes a wide variety of feed and stacking options as well as numerous optional features.

THE BENEFITSIn robot mode:

- Highly efficient batch size 1 production with up to 800 parts per shift

- Low unit costs per part

- No operating personnel required

In manual mode:

- Full freedom when handling cutting tasks

- Maximum flexibility

- Excellent for cutting packages or dividing thin panels

intelliDivide — the optimization "software as a service"

Optimization software can be a key element for a company wishing to compete successfully in the woodworking market. And no wonder, since intelligently optimized cutting patterns save significant time, reduce the amount of material and resources used, and ensure efficient processes. This can now be achieved in a process that is more agile and automated than ever thanks to intelliDivide — the optimization "software as a service."

As many customers can tell you from their own experience, when it comes to cutting patterns, one or two hours of costly work preparation time can be spent manipulating or correcting optimization results over the course of a day. Thanks to intelliDivide, this time can be reclaimed for tasks that add value, as this preparation time is no longer necessary.

How can that be, you might ask? intelliDivide is cloud-based optimization software that forms part of the tapio eco system and can be use directly via the Internet. All that customers require is Internet access — there is no special hardware or software that has to be installed locally.

intelliDivide is flexible and powerful

Simply upload the cutting data and intelliDivide automatically begins the optimization process, calculates several alternatives at the same time, and presents them as options for selection in the shortest time possible.

It doesn't matter if the customer is focusing on reducing waste, achieving the shortest machining times or optimizing handling: They merely have to select their preferred optimization result, download the data, and begin the cutting process. "This works because intelliDivide even takes over the machine configuration automatically if the saw is tapio-ready and connected to tapio," explains Arne Mömesheim, Product Manager at HOMAG Plattenaufteiltechnik GmbH, adding: "Our new range of HOMAG saws are tapio-ready as soon as they leave the factory."

Ideal for customers from trade and industry

Both trade and industry are set to benefit from these new possibilities. Small and medium-sized businesses can sharpen their competitive edge with this innovative optimization solution, as they can now receive excellent optimization results for cutting without investment, update, and maintenance costs.

In addition, the cost of using intelliDivide can be calculated with precision and displayed for comparison in a clear format. Charges depend on usage and are based either on yearly or monthly contracts. intelliDivide can also lead to a noticeable increase in added value for manufacturing companies with considerably large optimization volumes. This is due to the fact that this cloud-based optimization software uses higher computing capacity than any offline solution, and can also provide users with a calculation of the cutting time using real usage data in addition to the numerous optimization options.

THE BENEFITS

- The user does not require any local hardware or software. intelliDivide works independently of the operating system and on any mobile or stationary device with Internet access

- Users do not have to worry about maintenance or updates

- intelliDivide automatically calculates several alternatives at the same time

- Comparing the optimization results is quick and easy

- The costs for intelliDivide are dependent on usage and be calculated with precisio

- More information: www.tapio.one

New ideas for every type of production

Flexible workshop concepts

At Treff, HOMAG is presenting three production concepts — from small to large, from simply networked to digitized, from manual machine operation to automation solutions.

How can companies expand their production? How does networking work?

HOMAG has combined machines for different concepts. Visitors to Treff will discover new ideas for even more modern and flexible working — from trade to industry.

Concept 1: Workshop for small businesses

The simplest entry level for efficient production: this covers nearly all production steps for interior fitters.

The machines:

- SAWTEQ B-130: Small entry-level saw for efficient cutting, barely any different in price when compared to a sliding table saw (check out our promotion: currently with module45 bevel cut unit at a discount)

- EDGETEQ S-240: Entry-level machine for edge banding with initial automation of units

- CENTATEQ P-110: CNC processing center for routing and drilling with free access on all sides (including 5-axis technology

Concept 2: Flexible workshop with automated workpiece handling

With this concept, companies take the first step into partially unmanned production. The integrated saw is equipped with a robot, which operates the automatic destacking. The result: high performance with low personnel requirements.

The machines:

- NEW! SAWTEQ B-300 flexTec: Single saw with lifting table and the option to continue production unmanned for long periods through the use of robots. The brand-new saw concept using robots is making its world premiere at HOMAG Treff in Holzbronn.

- EDGETEQ S-380 profiLine: Edge banding machine with return and full automation

- DRILLTEQ V-500: Vertical processing center with routing unit for Clamex connections and return system (compact handling concept on 25 m², provides a performance boost of 15%)

Concept 3: Workshop with fully automated individual machines

This workshop takes you even deeper into the world of "automation." For example, it is possible to directly interlink the SAWTEQ B-320 flexTec with the edge banding machine. Parts that do not require edging can be destacked automatically. Production can be operated unmanned over a longer period, because where there is direct interlinking, no stack positions need to be emptied. In short: This is an industrial solution for batch size 1 production for requirements of any kind (including profile parts), which works with minimal personnel involvement.

The machines:

- SAWTEQ B-320 flexTec: Panel dividing saw with outfeed roller conveyor, two stacking stations and automated parts labeling

- SAWTEQ B-300: Fully equipped saw for maximum output

- CENTATEQ N-500: Nesting machine with roller conveyor

- STORETEQ S-200: The above machines are networked with this intelligent horizontal storage system(with flexible universal suction rail ST71). This ensures maximum flexibility from the storage system

- DRILLTEQ D-500: CNC drilling and dowel driving machine with intelliGuide operator assistance system

At Treff, HOMAG is also exhibiting two further concepts in higher performance classes. Further information can be found at: www.homag.com/treff

Concept 4: The "autonomous cell" (flexibly networked individual machines with TRANSBOT)

-

Can be seen in Schopfloch

Concept 5: Fully automated furniture production for China

-

Can be seen in the new production hall in Horb am Neckar (near HOMAG Treff in Schopfloch)

All concepts have one thing in common: integrated parts labeling. This part identification allows every part to be assigned in a clear manner during ongoing operation. Moreover, it enables easy reproduction in the case of reject parts.

CONCEPTS LIVE

This is where visitors can view the concepts at HOMAG Treff:

- Concept 1–3: Holzbronn

- Concept 4: Schopfloch

- Concept 5: Horb am Neckar

Information on how to get there and on all locations of HOMAG Treff can be found here: www.homag.com/visit-us

Workshops. Knowledge from practical experience.

Exchanged with experts.

We have prepared practical workshops dealing with current topics especially for visitors to HOMAG Treff. Take advantage of this opportunity to exchange knowledge with your colleagues and HOMAG experts.

Workshops in Holzbronn:

- Digital products for panel dividing technology

- Digitization: What is changing in terms of trade and medium-sized businesses in our industry?

- Intelligent logistics as the key to success

Spaces are limited — sign up now! Application deadline: September 15, 2018

The SAWTEQ B-200 saw brings power to the trade

First appearing at HOLZ-HANDWERK 2018, this lifting table saw is continuing to bring power to the trade at HOMAG Treff in Holzbronn. The compact saw supplements the existing 2 series from HOMAG, which previously consisted solely of a saw without a lifting table.

The technical highlights: In both versions, the machines have a saw blade projection of 60 mm — with higher projection available as an option. However, thanks to its integrated lifting table, the saw's technology is capable of substantially higher throughput. It can be loaded by forklift truck with entire books of panels, which are then automatically pushed onto the rear machine table one at a time to undergo the cutting process. This saves time, improves ergonomics, and accelerates the production process.

There is also a range of impressive additional equipment options available, such as the destacking module LITE, which is available for the SAWTEQ B-200. This module is operated using an integrated assistance graphic that uses color coding to clearly and accurately indicate the correct destacking position at all times. Furthermore, anyone who would like support during cutting can opt for intelliGuide basic. With this option, now available for the SAWTEQ B-200, LED signals at the cutting line show the operator the next work steps on the saw itself. The operator does not have to look at the monitor as often and can work in a smoother process with fewer errors.

Another new feature: Instead of the 600 mm wide air cushion tables, the SAWTEQ B-200 can alternatively be equipped with 800 mm wide cushion tables for improved ergonomics when handling large or heavy panels. For an even better performance, the saw can also be equipped with a 95-mm saw blade projection in addition to the existing 60-mm or 80-mm saw blade projection options.

intelliGuide professional: The intelligent operator assistance system

With the intelliGuide operator assistance system, saws are able to respond to the machine operators and display operating instructions in their immediate field of view so that operators no longer need to look at a monitor. At HOMAG Treff in Holzbronn, you can see the full version—intelliGuide professional—live in action. This version allows machine operators to benefit from all-round visual support. An LED strip at the cutting line lights up in different colors and lengths, allowing the machine operator to see the next action that must be performed. By employing a camera system, intelliGuide professional also detects where each workpiece is, then uses this information to tell the operator which workpiece needs to be inserted in the saw and in what way. If something runs out of sequence at this point, then the saw adjusts the processes or, if this is not possible, the system provides operating instructions via the LED strip or laser projection system, which is also included in intelliGuide professional. This system projects symbols directly onto the workpieces. The operator can then see what action needs to be performed, such as rotating, inserting or destacking a part, or placing it in intermediate storage. Example: If the machine operator puts a part down incorrectly, the laser projects an arrow symbol onto the part, showing the required direction of rotation. The machine operator must rotate the part correctly before the icon disappears and cutting begins.

Video at https://youtu.be/QBZU6eiyiVo