HOMAG Treff 2020: Technology and innovation

Prospective customers can experience the market leader’s solutions not only on the digital platform at live.homag.com, but also via individually bookable face-to-face meetings.

Due to the current situation, this year’s HOMAG Treff will take place in a new format. Prospective customers can experience the market leader’s solutions not only on the digital platform at live.homag.com, but also via individually bookable face-to-face meetings. The focus here is on machines, assistants and services that, on the one hand, can unburden companies in trade and industry in light of the current, challenging situation, while simultaneously increasing efficiency on the other.

The portfolio ranges from comprehensive consulting services for increased transparency in operations, optimised robotic sawing and efficient sanding-belt management to automated adhesive changes during edge processing.

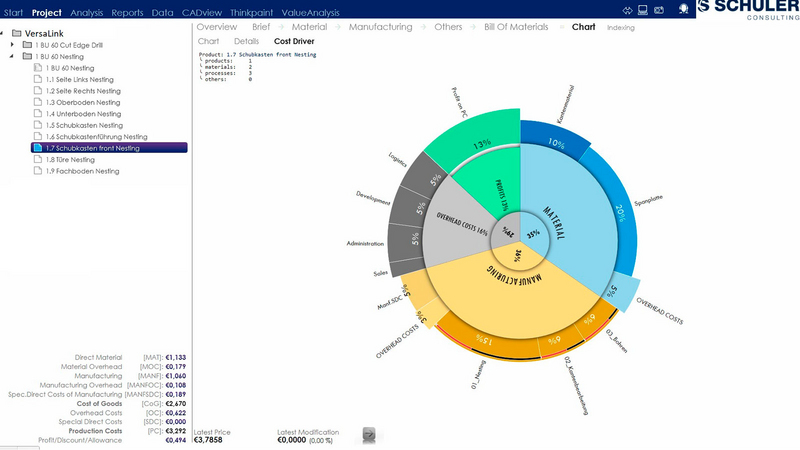

Design to Cost – for transparent analysis of product costs

Any company that wants to bring modern and creative furniture to the market at competitive prices needs an equally modern and creative solution in production: “Design to Cost” from SCHULER Consulting. On the basis of the relevant marketing and sales concepts, customer products are analysed in terms of costs, efficient production and complexity. The furniture industry thus benefits in many ways – transparently calculated actual product unit costs, best-practice calculations, optimised product costs through design adaptations, exact pricing and targeted decision-making recommendations regarding technology investments – all of these factors increase the efficiency of any company.

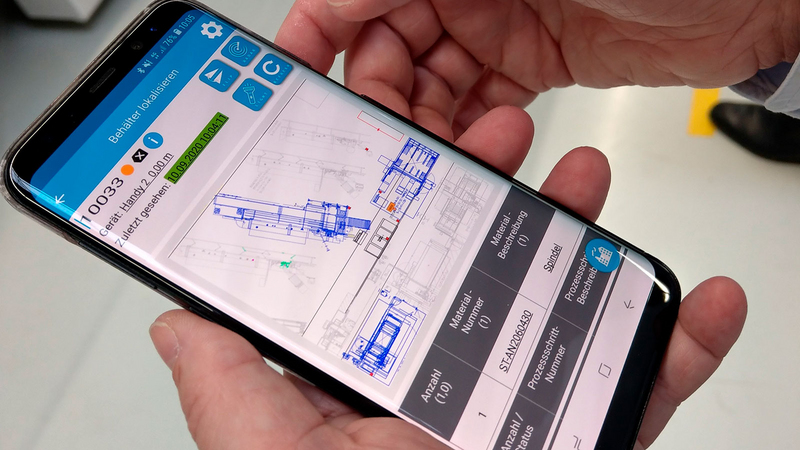

100% production transparency – comprehensive value-stream analysis

This paperless system allows SCHULER Consulting to get a direct grip with the heart of the operation: the intralogistics processes. Without time-consuming and cost-intensive IT solutions, the experts at SCHULER Consulting analyse the value streams via real-time tracking and create transparency using key figures such as buffer stock, waiting times, etc. This data is then used to generate concrete recommendations for practical action.

productionAnalyzer – the entire production facility at a glance

Companies in the woodworking and furniture industry are often faced with the same questions: how and when is their machinery fully utilised? What is the actual output of the individual production machines? And how can their efficiency be improved? The productionAnalyzer from HOMAG provides trade and industry with a complete overview – real-time machine status, evaluations of key performance indicators and potential for improvement, all at a glance.

The productionAnalyzer shows the performance of your machinery – no matter when and where you need this information. Clear graphics illustrate the component performance and machine status. In this way, potential improvements can be identified and exploited via the app.

intelliOptimizer Stacking – cutting-plan sorting for optimised stack formation

HOMAG customers working with a SAWTEQ B-300/B-400 flexTec robot saw can now improve production when it comes to cutting – with intelliOptimizer Stacking. This intuitive web application provides customised stacking strategies and a detailed stack preview for all cutting plans for a particular job. The results can then be easily transferred directly to the saw.

The tool reduces the number of stacks, the number of required stack changes and the amount of space required by at least 20 per cent via consistent stack-based re-sorting of the cutting plans. On the one hand this improves pallet utilisation by the robot and on the other hand it extends the intervals between stack changes. The result? Extended production times without an operator, because the saw can cut parts autonomously over even longer distances. In concrete terms, this means less downtime, increased output during robot operation and reduced working time.

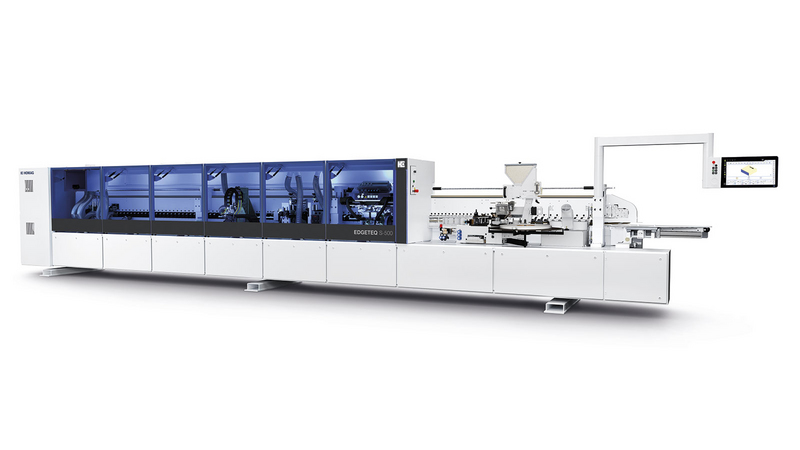

EDGETEQ – innovations in edge processing

In the feed-rate class up to 20 m/min there are some new features for the EDGETEQ S-380 for carpenters and joiners. For example: a motor-driven top roll pressure unit, a small-parts package with narrow roller pitch, automatic adhesive dosing as well as the YOURPLUS package that includes the digital assistants MachineBoard, ServiceBoard and ServiceAssist. These features increase workpiece output and ensure that the joints are of a consistently high quality, while also adding flexibility.

The EDGETEQ S-500 in the feed class up to 30 m/min focuses on high-quality acrylic edge processing and automatic changing of the adhesive type or colour, as well as automatic adhesive dosing. Ultimately, many carpenters and joiners often need to quickly change the adhesive type and/or colour during their daily work. Until now, this has required extensive and time-consuming manual work. The new solution provides a remedy here – by allowing customers to conveniently switch between PU and EVA, for example.

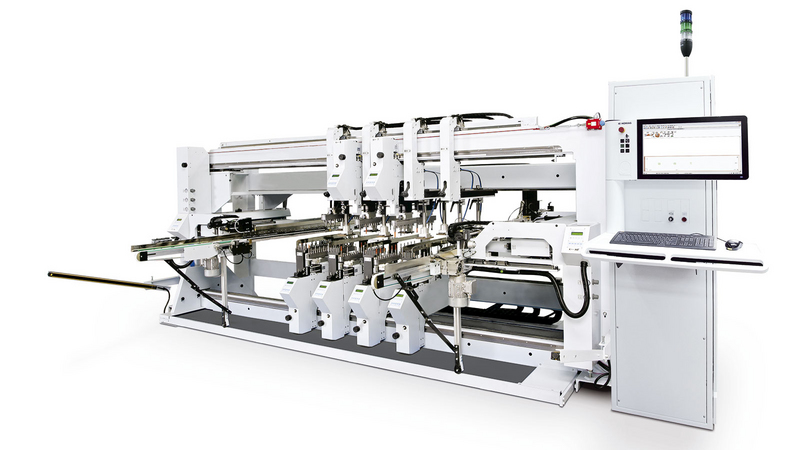

DRILLTEQ – redefining high-performance drilling

One highlight in the CNC segment concerns the DRILLTEQ C-500. Besides allowing a drilling rate of 26 parts per minute, HOMAG has also integrated a corner saw unit with variable cutting angle to cut the corners of the workpieces in the same work step.

SANDTEQ – universal unit with planetary cassette

Three-dimensional surfaces in general – and the fine and intermediate lacquer sanding of profiles and frames in particular – often present a challenge in day-to-day work. Machining with the aid of a planetary cassette is a technically challenging but convenient solution for the operator. The pick-up is performed by a universal unit, while operator guidance is provided by toolManager. The cassette is designed to allow quick and easy replacement. Cassette identification is automatic thanks to the HOMAG coding system. Various settings can then be configured via the terminal: the abrasive feed, direction of rotation and the infinitely variable frequency-controlled cassette oscillation with 36 to 240 strokes per minute. This guarantees optimum quality and a long service life for the abrasives.

SANDTEQ – sanding-belt organisation system

Optimum sanding-belt storage is important, for example to prevent damage – however, tidiness, cleanliness and clarity are also essential. After all, carpenters and joiners need to know where each sanding belt is located and whether enough of each type are available. HOMAG offers a practical solution in the form of the Sanding Belt Management Set. This innovative package of hardware and software has already proven itself in the edgeband sector. During the work preparation phase the master data is maintained using materialManager, which serves as the company’s central material administration system. Using a tablet and the material management app, materialAssist Sanding, the operator then has all relevant information at hand while standing directly at the sanding-belt shelf – grain type, backing, grain size, manufacturer and dimensions. With the aid of an LED display on the shelf, the required sanding belt can be easily identified at a glance. This saves time – and ultimately also money.