Consistent single-piece production for windows: Complete solutions — from planing to the surface

Do you want to produce 15 or 50 window units per shift? Which processing steps do you want to perform? Do you want to use profile splitting? Do you want to process arches and doors too? The performance and processing range of the CENTATEQ S-800/900 series can be tailored to meet customer requirements.

These properties make the CENTATEQ the optimal core of a complete system for window production from one source.

HOMAG is now taking the next step — with integrated solutions for single-piece production.

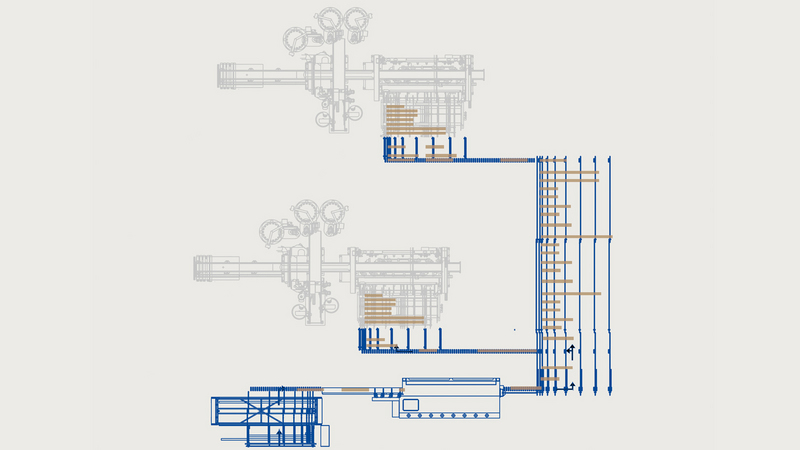

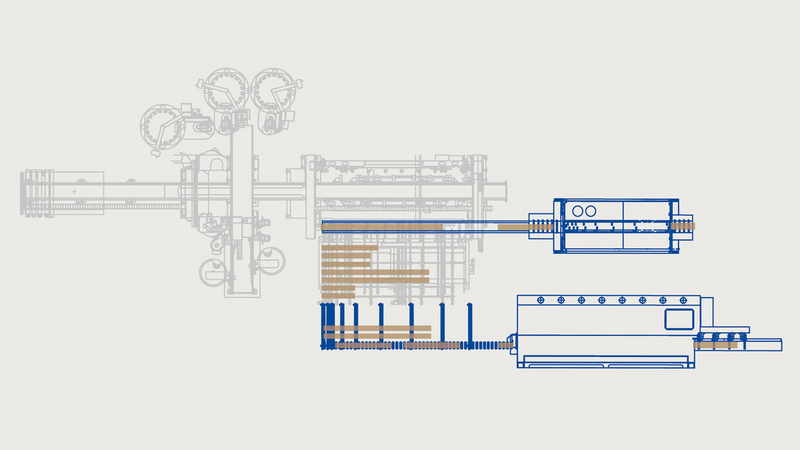

How? By combining expertise in planing, CNC and surface technologies. The CENTATEQ S-800/900 series forms the basis. The ideal partner for planing is the MOULDTEQ M-300 (previously LPP 300) with intuitive powerTouch operation and a quick-change system for tools. The glass fixing rail can be detached using six spindles and planed to a finish top and bottom. Machines are used to impregnate or varnish the single window parts for the perfect finish to the surface. Finally, window manufacturers will thus be able to take advantage of tailor-made approaches for ready-to-mount and all-round perfectly coated parts for windows, regardless of whether 25, 50 or more units are to be produced on a single day.