CNC technology — world premiere at HOMAG Treff

Nesting redefined.

Nesting redefined. World debut of the CENTATEQ N-210 and N-510 models. Comprehensive new solutions for efficient working with maximum flexibility

HOMAG is presenting a new CNC series for nesting applications to allow for the complete processing of workpieces. This series will cater to current wishes as well as future requirements — from entry-level trade through to industrial orientation or suppliers. Customers can experience the new CENTATEQ N-210 and N-510 models live at HOMAG Treff in Herzebrock.

Improved handling and increased output were the clear areas of focus in the development of the new nesting series. Key features include ten different table sizes and eight automation concepts, which are optimally designed to meet customer demands. The latest generation is automated and works in single operation, from three-axis technology to five-axis technology and on table sizes ranging from 1.25 x 2.5 m to 2.1 x 7.4 m in half-sized or full-sized format.

The result is a nesting platform that takes advantage of innovative functions and the guiding principles of energy efficiency in equal measure. The main components are a highly modular, switchable vacuum and air cushion table concept as well as newly designed suction components that have been optimized using CFD flow simulation. There are also innovations in the area of workpiece handling.

Customers can look forward to a modular concept that can be easily expanded via plug and play. Automation on the machines can also be very easily supplemented for all series, from small to large.

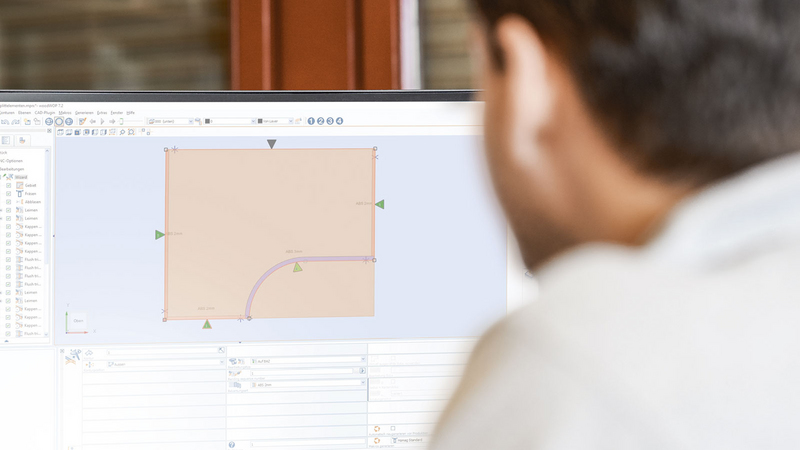

woodWOP 8.0: New functions. Infinite possibilities

With more than 30,000 equipped machines and over 60,000 licenses sold, the success story of woodWOP is clear. The focus of the easy-to-use workpiece-oriented-programming (WOP) system is its innovative large graphical area, in which the workpiece is displayed in three dimensions. The relevant processing diameters can be entered and realistically displayed in the graphic to program trimming and drilling operations and saw cuts quickly and easily.

The next version, 8.0, offers plenty of new functions that have been developed together with woodworkers. Thus far, the involvement of customers and a willingness to listen to the target group has always set HOMAG apart from the competition, and this has also been taken into account in the latest development of this software. The focus is on practical assistants for convenient processing.

Users can look forward to the following innovations:

- The contour assistant provides comprehensive support for beginners when programming non-rectangular workpieces.

- The feature recognition not only detects bore holes but also pockets and grooves in a 3D workpiece model.

- Auxiliary graphics, additional attributes and the form view simplify the operation of extensive variable tables.

- With the new gluing wizard, workpieces for edge banding can be programmed even more efficiently.

- The formula assistant easily defines even highly complex formulas and thus offers another option for advanced users.

- To simplify and increase efficiency, tried and tested settings can be stored in the CAM plug-in for similar applications.

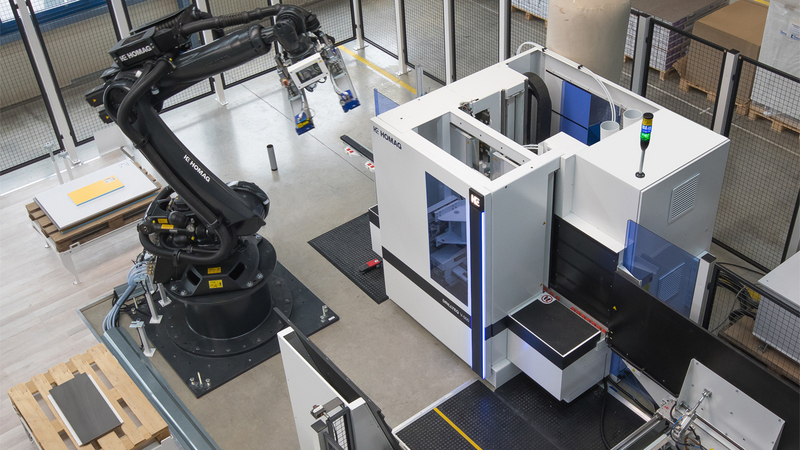

Robotic part handling and management with vertical processing centers

With uptime of approximately 100%, high repeat accuracy and pinpoint part handling, robots are reliable partners and increase the cost-effectiveness of production. The reliable, integrated parts supply makes every CNC machine a high-performance center and therefore a complete, optimal manufacturing cell for production.

The FEEDBOT D-300, a six-axis robot, assumes automated parts handling for the DRILLTEQ V-500 vertical processing center. Unlike in the past, integration into cell control will no longer be necessary. The robot and the machine are still guaranteed to be simple to operate. Additionally, functions such as aligning, validating, and rotating of parts can easily be integrated into the process. It is also very simple to implement new workpieces during the process.

The advantages of robot management are a space-saving concept, handling that protects the material and the surface, and reduced workload for personnel.