The recent rise in sales had put pressure on the manufacturing side of the business to keep up with demand. To alleviate the situation, the directors made the strategic decision to invest in the latest CNC machinery which would increase the capacity and improve efficiency at the Cottingham site.

“We looked at a number of options in the market, but settled on HOMAG,” explains CNC production manager at Swift, Dave Smith. He continues, “The Group already had edge banders and BHX 050 drilling centres from HOMAG and the excellent level of support we have had from them in the past certainly helped in the decision process. Our maintenance department, in particular, is pro HOMAG. It prefers dealing with HOMAG partly because of the level of aftersales service we get from them. We know that if we call with an issue they will come back to us with a solution quickly. In addition, the machines have self-diagnostic systems, so HOMAG engineers can log in and sort out issues remotely. Also, from the maintenance side, the manuals and electrical diagrams are of a very high standard and make it much easier for our own maintenance people to service the machines when necessary.”

Live demonstration sealed the deal

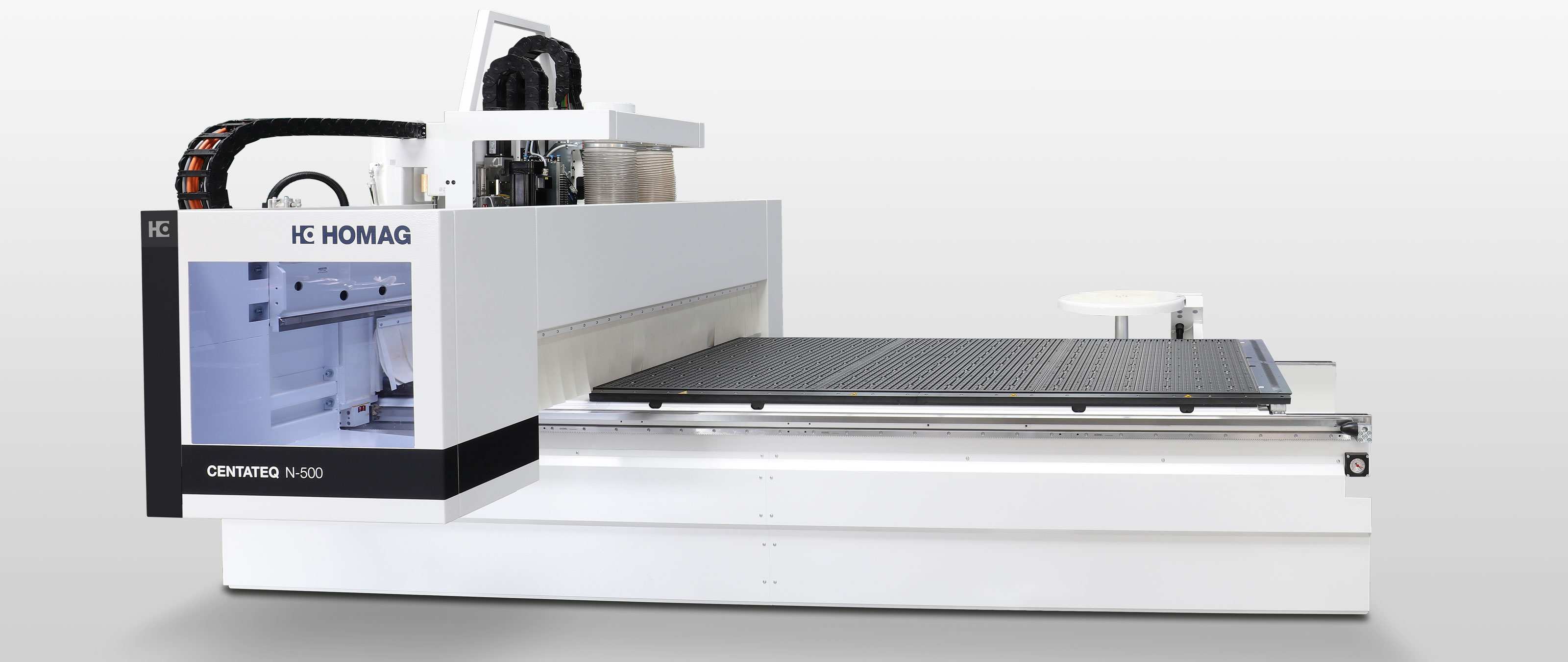

“John Shepherd, our HOMAG area sales manager, invited us to Castle Donington for an in-depth demonstration of the HOMAG Vantage 100 machine. For this, we were able to take along materials we work with and some of our programs and run them through the Vantage 100 to see how it coped. The results were really impressive. The machine uses the powerTouch operating system which is very intuitive and easy to use. Seeing the machine in action sealed the deal. It was clear that this was the machine that would give us the increase in capacity we were looking for whilst maintaining the high quality and reliability that we demand. Our manufacturing processes include a high number of drill cycles and the old CNC machines we used had no drill blocks which led to a lot of time consuming tool changes. The configuration of the Vantage 100 includes a drill block with 12 positions, so the need for tool changes is minimised, making our production so much more efficient.”

A compact, clean solution

“Another benefit of the HOMAG Vantage 100 is its small footprint. We do not have a lot of spare space in the factory and we needed to install two Vantage 100s, so the compact size of the machine is very important to us. We also like its self-cleaning aspect. Previously, the old machines needed frequent cleaning; we had to clear away the dust and then vacuum the machines down. The new Vantage 100 has a cleaning cycle which automatically kicks in once the components have been machined and the table is clear. All the debris is taken away by a built-in waste and vacuum system underneath the table. So, supported by the main dust extraction system, there is virtually no dust left to gather on the equipment and surrounding areas. Compared to our old machines, this feature saves us a significant amount of non-productive time.

“These new machines from HOMAG have made a huge difference to the efficiency of our operation because they’ve enabled us to reduce cycle times. As a consequence, we no longer have to put CNC work out and despite running much quicker, the quality has remained high. We’re delighted with our investment and would recommend HOMAG to anyone seriously wanting to improve their processes,” concludes a happy Dave Smith.

A powerful and versatile CNC

The HOMAG Vantage 100 nesting machine offers a wide selection of router heads, tool changers and drill block configurations to enable individual customers to specify their ideal machines. The Vantage range can be supplied as stand-alone models or throughfeed systems with automatic material handling and part identification. They can even be integrated into HOMAG’s increasingly popular board storage and retrieval systems. This enables material to be called from stock on demand and fed directly onto the machine table without any operator intervention – perfect for ‘make to order’ production.

If you would like more information or a demonstration of any of the HOMAG CNC machinery, please contact HOMAG UK

“We looked at a number of options in the market, but settled on HOMAG, Swift already had edgebanders and BHX 050 drilling centres from HOMAG and the excellent level of support we have had from them in the past certainly helped in the decision process”Dave Smith, CNC Production Manager at Swift Group