With over 20 years’ experience in the kitchen and bedroom industry, Ocean Kitchens had become tired of relying on external manufacturers to supply carcasses and edged doors. Consequently, in 2018 the company made the decision to set up its own manufacturing facility in Beoley near Redditch, six minutes from junction 3 on theM40. This was a significant move for the family run business and one that potentially carried a high risk element.

Ocean Kitchens’ managing director, Martin Beech, takes up the story: “It’s been a long-term ambition of mine to expand into the manufacturing side of the business and last year things came to a head. We were frustrated at being let down by suppliers whose quality was variable and delivery often slow. So, after much soul-searching and discussions with various people, we decided to take the plunge.

“To keep business separate we decided to set up Carkus Solutions as our manufacturing arm. Ocean Kitchens would continue to trade, servicing the house builders and consumer customers, whilst Carkus Solutions would offer a trade only service to kitchen retailers.

“I have long had a passion for German design and engineering and I wanted Carkus Solutions to offer a true German handleless kitchen product. To achieve this an aluminium rail has to be routed into the cabinetry. On the horizontal recess between the worktop and the door/drawer, an ‘L’ shaped continuous aluminium rail runs along the entire length of the cabinet.”

Selecting the best machine partner

“In drawing up our machine inventory, therefore, we had to ensure that we specified the equipment capable of manufacturing this style of carcass. Whilst we talked to a number of different machine manufacturers, I have to admit that the superb reputation of German engineering influenced my initial thoughts. This bias was further weighted with the candid advice and input we received from Matt Long, HOMAG UK’s area sales manager.

“Early on in the process I had been extremely impressed with the BHX 050 CNC drilling machine, especially given its small footprint. At 7,000 sq. ft., our new manufacturing facility could hardly be called spacious so a compact powerhouse like the BHX 050 seemed ideal.

“There was one drawback though; the 050 wouldn’t give us the capability to do the necessary routing for a true German kitchen design. Matt Long pointed out, however, that the BHX 055 with its four router heads would be perfect for the job.

“Matt’s input regarding specifying the right edge bander, one that would deliver seamless edges, and a panel saw that met our needs was invaluable. The package he then worked out for us to buy all three machines sealed the deal. Matt was even able to sort out the purchase for us over a five year term through HOMAG Finance – it was all very straightforward.”

Comprehensive training and first class aftersales service

“Once the machines were installed the HOMAG engineers trained up our team and I have to say they did an excellent job. Their engineers certainly know there stuff; they not only trained our team on how to operate the machines efficiently, but also were able to impart lots of really useful hints and tips of the trade regarding different materials and process hacks.

“Of course, the HOMAG woodWOP software is fantastic, as you would expect; it is on a completely different level to anything else on the market. The latest version gives the operator so much visual support; you can even view how an operation is going to be done prior to actually carrying out the work. What’s more, it is easy to learn and quick to use; it makes manufacturing life so much easier and more efficient.”

Cut, edged, routed and drilled

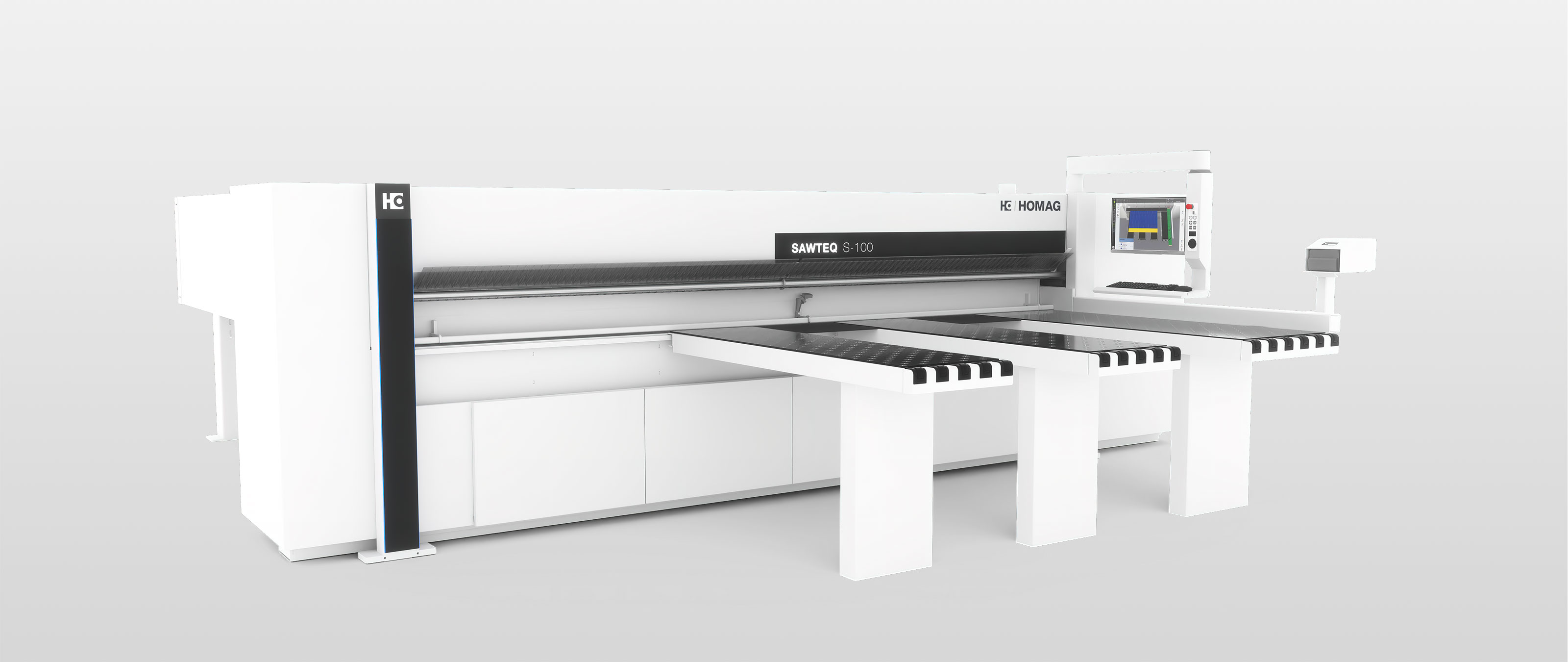

The package HOMAG put together for Carkus Solutions included the SAWTEQ B-130 panel saw, the EDGETEQ S-240 edge bander and the BHX 055 CNC.

The SAWTEQ B-130 panel saw costs hardly any more than a well-equipped sliding table saw, while providing a much more precise and efficient cutting process. This is achieved by proven HOMAG technologies and a clearly perceptible increase in automation and processing capabilities. In short, the SAWTEQ B-130 panel-sizing saw makes it easier to enter the world of precision manufacturing which was just the ticket for Carkus.

The S-240 edge bander can handle edge thicknesses up to 3 mm and workpiece thicknesses up to 50 mm. It comes with the option of a joint trimming unit for a perfect cut and an optimum glue joint, plus a profile trimming unit for rounding corners. An essential feature for Carkus Solutions was the airTec unit which gives the perfect zero joint finish they were looking for.

The BHX 055 CNC (now known as the DRILLTEQ V-200) vertical CNC processing centre is a versatile machine for drilling, trimming and grooving. It saves time, space, energy and money, and is particularly well-suited to just-in-time production for trade, small businesses and also custom production in large companies.

Transforming business

Martin Beech again, “The manufacturing cell that HOMAG has provided us with puts our business in a completely different league. We are delighted with the investment which looks set to pay for itself within three years.

“Naturally, there have been hurdles to overcome, but I have to take my hat off to HOMAG’s service support which is second to none. When there’s been an issue they’ve owned the problem and sorted it straight away; it’s been very impressive.

“The products we can produce with this neat manufacturing cell are excellent, both in terms of quality and speed of production. More importantly, perhaps, the kit is consistently reliable, allowing us to make premium products efficiently whilst also making a reasonable margin.

“Partnerships are all about people, and the folks at HOMAG UK are not only totally professional, they’re also truly passionate about their work. They really want to see their customers doing well; they take responsibility for their installations and are always asking how they can help to provide continuous improvement,” concludes Beech.

If you’d like a demonstration or more information about HOMAG edge banders, the DRILLTEQ range of CNC drilling machines or SAWTEQ panel saws, please contact HOMAG UK on 01332 856424.

“Partnerships are all about people, and the folks at HOMAG are not only totally professional, they’re also truly passionate about their work. They really want to see their customers doing well; they take responsibility for their installations and are always asking how they can help to provide continuous improvement.”Martin Beech, Ocean Kitchens’ managing director